This is a hardware workshop, it is mainly used to produce metal components for weight scales, such as scale pillar, pan, display shell, etc. These components undergo three processes-stamping, welding and coating. This advanced workshop is equipped with press machines of different standards, 180 sets of fully automatic high-speed press machines, 50 sets of automatic welding robots, 2 electrostatic coating lines and 70,000 metal weight scale components introduced from Japan. In addition, because our workshop is equipped with such a diverse and comprehensive array of production equipment and molds, like our mold change system and PVM self-protection technology, we are able to easily respond, adapt to and quickly satisfy client’s needs and custom requests.

This is our weight sensor manufacturing workshop. It is equipped with the following: CNC milling machine, CNC bench drilling machine, CNC laser marking machine, laser cutting machine, fully automatic glue dispensing machine, and other high-precision manufacturing and detection equipment. The equipment is used in cutting, drilling, grinding, mounting, welding, glue dispensing, packaging and so on. Because our workshop is fully equipped we can produce more than 80,000 weigh sensors within a single day.

20 robotic arms are installed in the injection molding workshop, which enables automatic feeding, shaping, and ricking. The reduces both the production time and labor costs while enhancing manufacturing and product precision.

The main function of the electronic component manufacturing workshop is the production of display screens, motherboards and the button board. Concurrently, the diverse automatic equipment installed in the workshop allows us to adapt to a wide array of client needs. This section can produce 180,000 pieces of electronic components. They will be sent into the assembly workshop after undergoing reliability and quality control tests.

The electronic scale assembly workshop is the place where components are assembled. There are 22 assembly lines, and the assembly capability of the workshop reaches 50,000 scales per day.

The platform scale workshop is mainly used to manufacture electronic components, our truck scale, crane scales, mechanical balance and other products. Its manufacturing capability is more than 20,000 scales daily.

For quality control purposes, we have designated a specific area for aging process and quality testing of semi-finished products. The area spans 1,000m2. The process guarantees sufficient longevity of products before they are shipped. Moreover, full inspection of our products is completed in the workshop, which ensures high reliability and excellent quality of our weighing scales.

Injection molding workshop occupies an area of 200 square meters. And it has 86 sophisticated staffs and 42 injection molding machines. These injection molding machines are of different standards, ranging from 200g to 1200g. Besides that, the workshop has strong manufacturing capacity, which could produce 60,000 plastic components for weighing scales within a single day. And the plastic components manufactured in the workshop possess good uniformity and durability. They are qualified for the drop test delivered by customers.

Full view of plastic component manufacturing workshop

Full view of plastic component manufacturing workshop Full view of injection molding machines

Full view of injection molding machines

20 automatic robot arms are installed in the injection molding workshop, which enables automatic feeding, shaping, and ricking. Adopting these robot arms saves much human cost and increases the precision and the quality of products. Besides that, adopting robot arm effectively reduces the product consumption and quality problem caused by manual operation.

Robot arm for CNC injection molding machine

Robot arm for CNC injection molding machine Close-up view for picking part of robot arm

Close-up view for picking part of robot arm

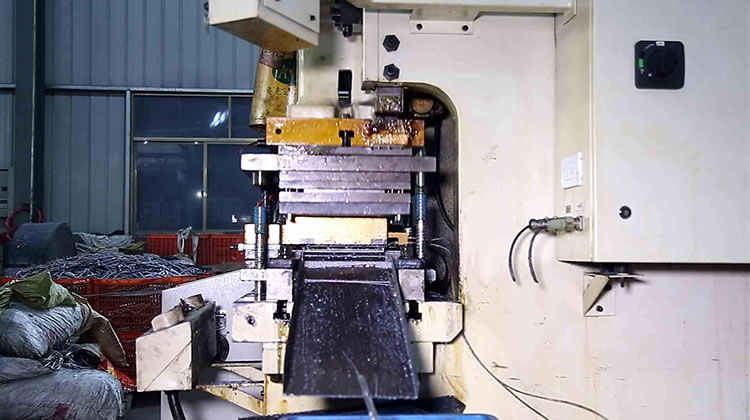

Metal production workshop covers an area of 1,200 square meters, and is the home of 82 employees. It is equipped with 63 machines, including diverse press machine, hydraulic tensile testing machine, spot welder and other equipment. They could be used in diverse processes, such as cutting, drawing, metal punching, trimming, crimping and so on. Besides that, the machines all have a fully automatic infrared protection device. When the security of the equipment is guaranteed, the production capability of the workshop is quite large, with stainless steel components of electronic platform scale more than 20,000 sets, and weighing pans of different standards more than 50,000 sets. Moreover, since diverse equipment and molds are installed in the workshop, and automatic mold change system and PVM self-protection technology are adopted in the workshop, customers’ needs could receive a fast response.

Full view of metal component manufacturing workshop

Full view of metal component manufacturing workshop Full view of tensile strength tester’s production line

Full view of tensile strength tester’s production line

10 hydraulic deep drawing presses of different standards are installed in the processing section. These machines could be used to deliver deep drawing process. Its main product is steel display shell. With this process, the strength of products could be increased, and these products possess a reasonable assembly room.

Full view of deep drawing press

Full view of deep drawing press Close-up view for deep drawing press’s operation

Close-up view for deep drawing press’s operation

50 sets of automatic welding robots are equipped in the area, and these welding robots are from different models. They are mainly used to weld all kinds of metal components, such as scale pillar, standing column and weighing pans. The production line is qualified for automatic welding, which saves human resources and lowers the labor cost. Besides that, the metal components welded in the production line feature high uniformity, good welding beads and high welding firmness.

Automatic robotic welding line

Automatic robotic welding line Close-up view of welding robot

Close-up view of welding robot

In this section, there are 10 high-speed press machines, which are mainly used to produce all kinds of metal components. These machines have a large manufacturing capacity and their products have high uniformity.

Besides that, adopting these machines largely reduces staffing costs, and enables a basic realization towards unmanned production.

High-speed press machine

High-speed press machine Close-up view for high-speed press machine’s operation

Close-up view for high-speed press machine’s operation

There are two electrostatic coating lines in this section. These two lines all adopt eco-friendly technologies, so both the coating process and its products pose no damage to human being. Besides that, coatings all have a strong adhesive force, which means these coatings are tightly connected with metal components, and are not easy to fall off.

Coating line

Coating line Coated components

Coated components

Weight sensor manufacturing workshop covers an area of 10,000 square meters, and it is the home for more than 400 staffs. The workshop is mainly used to manufacture weight sensors. The main processes delivered here include cutting, CNC drilling, sand blasting, mounting, glue dispensing, welding, debugging and packaging. The workshop is equipped with 120 sets of CNC milling machines, 22 automatic sand blasting machines, and 220 sets of other automatic assembly equipment. These machines are from different standards. Moreover, the workshop has high manufacturing capacity, which could produce 100,000 weight sensors of different standards. These sensors could be used in diverse scales, whose weighing ranges are quite different, from 100g to 5T, and the highest accuracy is 1g. The workshop does not only assembly our weighing scales, it is also available for weighing scale manufacturers from home and aboard.

Exterior view for weight sensor manufacturing workshop

Exterior view for weight sensor manufacturing workshop Mr. Dai’ s introduction for weight sensor

Mr. Dai’ s introduction for weight sensor

Advanced CNC milling machines and supporting fixtures developed by Huaying Weighing Scale are adopted in the section. They are used to deliver milling and drilling processes, which possess accurate positioning and small engineering tolerance. Adopting these machines largely increases the production efficiency without sacrificing the product quality.

Full view for CNC milling machine

Full view for CNC milling machine Close-up view for local part of milling machine

Close-up view for local part of milling machine

10 high precision laser marking machine s are installed in the section, which produce no toxic materials during their operation. Besides that, label marking machines and fixtures are used together during the production line, which effectively lowers the engineering tolerance caused by manual operation, and doubles the working efficiency.

Sand blasting and line marking line

Sand blasting and line marking line Close-up view for line marking

Close-up view for line marking

There are 10 welding lines and complete detection equipment in the section. The detection equipment is used to deliver welding quality control towards inner part of weight sensor, which could guarantee good welding quality of electronic components in weight sensors.

Weighing scale welding line

Weighing scale welding line Close-up view for welding process

Close-up view for welding process

There are 5 production lines in this section, which ensures the rapidity, timeliness and security of product delivery. Besides that, we also set staff to deliver continuous checking during the manufacturing process, which guarantees the uniformity of production technology. Moreover, complete inspection is carried out for finished products, and only the qualified products could be delivered to customers.

SMD weight sensor production line

SMD weight sensor production line Close-up view for local parts of SMD weight sensor

Close-up view for local parts of SMD weight sensor

There is one laser die cutting machine, 4 mechanical cutting machines, and 2 high precision profile projector. They all possess high working efficiency and products manufactured with them enjoy high uniformity. Besides that, instead of microscope, large-size project is used to provide a clear vision and better control towards product quality.

Strain gauge production line

Strain gauge production line Close-up view for mechanical cutting machine

Close-up view for mechanical cutting machine

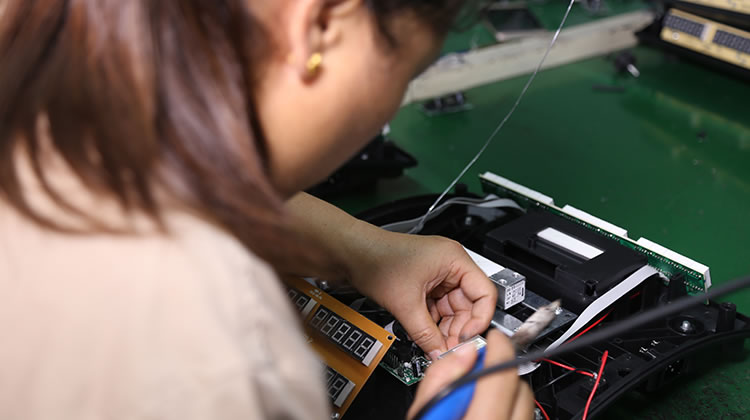

The workshop is mainly used to produce diverse electronic components, including display screen, motherboards and button board. Besides that, diverse automatic equipment is also installed in the workshop. It could produce 60,000 sets (180,000 pieces) of electronic components. They will be sent into the assembly workshop after undergoing reliable tests.

Full view of electronic component manufacturing workshop

Full view of electronic component manufacturing workshop Full view of automatic recording machine

Full view of automatic recording machine

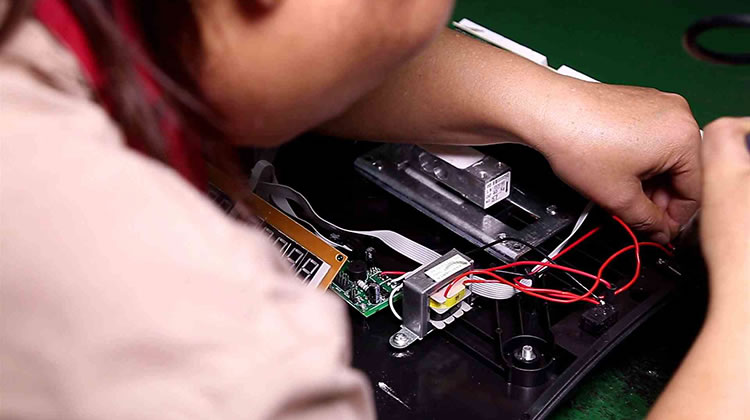

Electronic scale assembly workshop is the place where components are assembled. It covers an area of 10,000 square meters, and is the home of more than 300 staffs. There are 22 assembly lines, and the assembly capability of the workshop reaches to 50,000 scales within a single day. Besides that, there is also an area designed for aging process of semi-finished products. The area covers an area of 1,000m2. The process guarantees enough aging for products before they are shipped. Moreover, full inspection towards our products is delivered in the workshop, which ensures a high reliability of our weighing scales.

Full view of electronic weighing scale assembly workshop

Full view of electronic weighing scale assembly workshop Full view of assembly line

Full view of assembly line

During the process, the major job is to install battery, transformer, switch, socket, spirit level and other components on the pedestal of plastic components.

Electronic components’ assembly

Electronic components’ assembly Electronic components’ assembly

Electronic components’ assembly

During the process, the major job is to install motherboard, display components and buttons on the pedestal of plastic components.

Assembly for display screen

Assembly for display screen Assembly for display screen

Assembly for display screen

Place the same weight on four corners of the scale pan, and read the numbers. If the numbers are not same, a correction is needed.

Impact testing for weighing scale

Impact testing for weighing scale Parameter correcting

Parameter correcting

Deliver calibration with qualified weight. If a standard weight is placed on the weighing pan, the number displayed on the screen should be the weight of the object. In this occasion, the weighing scale is qualified.

Calibration for our weighing scale

Calibration for our weighing scale

In the process, the number of each display screen should be correct. The components should also be qualified. Besides that, the corresponding functions of the scale, and the flexibility of buttons should be checked. If there is any problem, the product will not be sent to the assembly area.

Full-inspection towards product

Full-inspection towards product

There is also an area designed for aging process of semi-finished products. The area covers an area of 1,000m2. An aging test will be delivered after 24-hour powered on. And the test is delivered to check whether there is any damage occurred during the operation. Besides that, the efficiency of self-protectiveness system of the circuit will also be checked during the test.

Full view of aging area

Full view of aging area Aging test towards products

Aging test towards products

Since Huaying Weighing Scale was founded, it built labs to deliver strict detection towards the components and products, which ensures the high quality of our products. Diverse detections are delivered in the lab, such as product endurance testing, constant temperature & humidity testing, leakage current testing, electrical insulation testing, high temperature testing and low temperature testing.

Full view for component testing in lab.

Full view for component testing in lab. Full view for product testing in lab.

Full view for product testing in lab.

Finished product warehouse covers an area of 15,000 square meters. And the warehouse underwent dehumidifying, ventilation, and explosion protection processes, which ensure safe storage. Besides that, finished products are placed scientifically, which guarantees a fast inputting and outputting. Besides that, the product will be delivered out first if they are stored first. Our products are exported to many countries and regions in Europe, America, Southeast Asia and so on.

Full view of warehouse

Full view of warehouse Local part of warehouse

Local part of warehouse

Products for foreign customers will always be delivered from Ningbo port, and they are always shipped by sea. When we finished the production process, customer needs to rent containers for product loading, and then the containers will be transported to Ningbo port for sea transportation.

Truck loading

Truck loading Product delivery

Product delivery

Yongkang Huaying Weighing Apparatus Co.,Ltd.

Add.: NO.20, Tianhe(N)Rd,Shihou Industrial Zone,Zhiying Town,YongKang City,Zhejiang Province,China

Tel.: +579-87433670

Fax: +579-87433126

E-mide: medy@cnhyhq.com